Technical

TECH TUESDAY: How teams cope with ‘brake killer’ Canada

Share

The Circuit Gilles-Villeneuve in Montreal retains its reputation as the biggest brake-killer on the F1 calendar, with its relentless sequence of low-speed bends interspersed by high-speed straights. How do the teams ensure their brakes survive the full 70-lap distance without giving up? Mark Hughes and Giorgio Piola provide the answers…

There are many things that make Canada’s track unique – the fact that it sits on an artificial island being one of them. But the crucial point about the circuit’s layout is that the straights are just long enough to allow high terminal speeds, but not long enough to give the brakes enough time to cool before they are needed again.

An F1 car's brakes are given a thorough workout in Canada - nowhere more so than into the hairpin, which follows a short blast out of a chicane. Lock-ups are common. © LAT Images

The brake discs on an F1 car are manufactured in carbon fibre as it gives vastly superior friction to the steel brakes that were used up until a couple of decades ago – and they also weigh significantly less.

But the one downside of carbon discs is their very narrow temperature operating band, and this is something the Montreal circuit makes apparent. The disc does not give adequate stopping power until it has reached around 400-degrees Celsius – but at anything much beyond 800-degrees Celsius it begins to oxidise. This process – similar to rusting of metal but in hyper-speed – sees the carbon literally turn to dust and if not controlled the disc would quickly oxidise into nothing. Not something any driver wants to consider…

Because it is so desperately important to keep the temperature of the disc within that narrow band, for Montreal the teams’ special preparations centre around increased cooling capacity to the brakes (even though this costs aerodynamic performance).

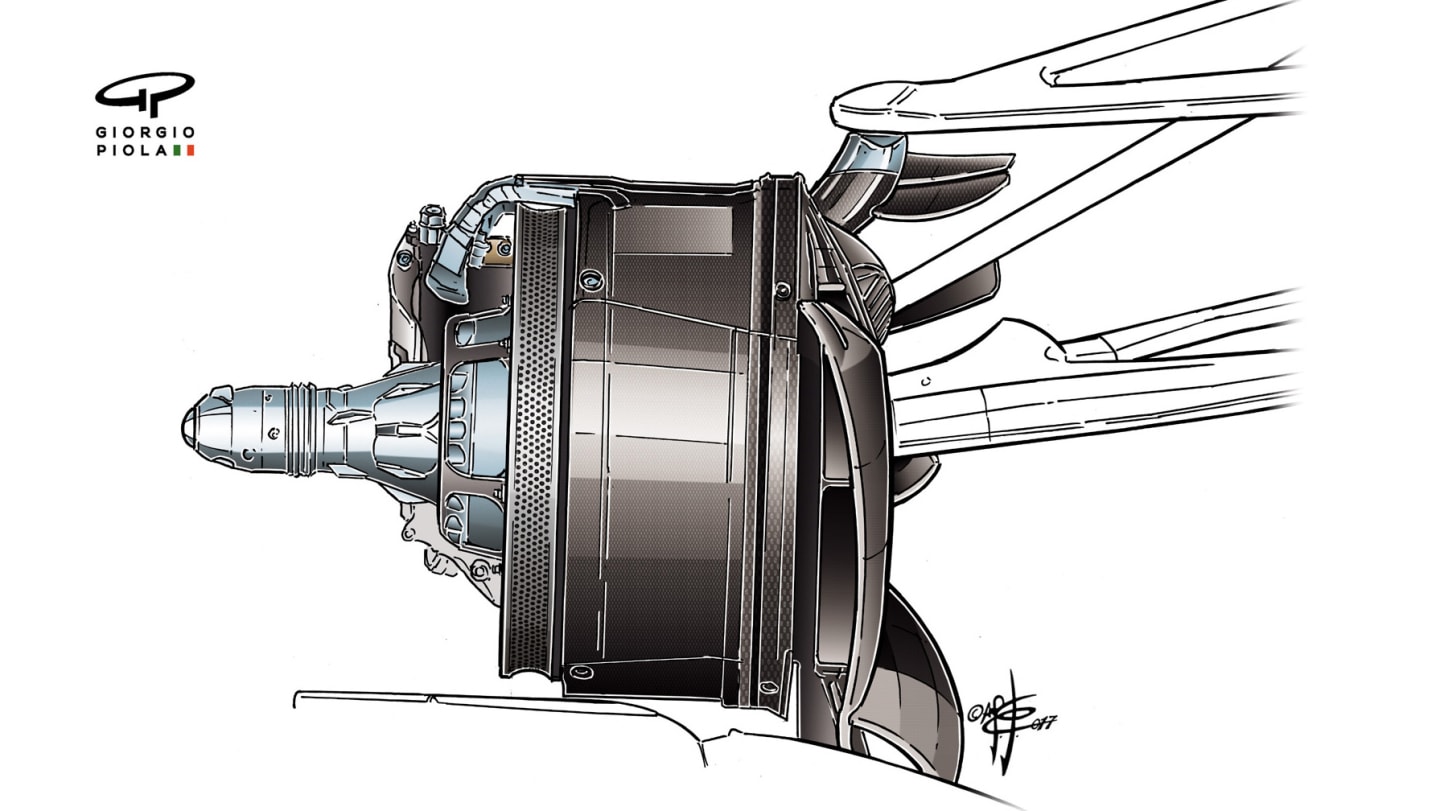

The most obvious way to improve cooling to the brakes is to increase the brake duct size. This image shows the front brake duct layout Red Bull used in Canada last year. © Sutton Images

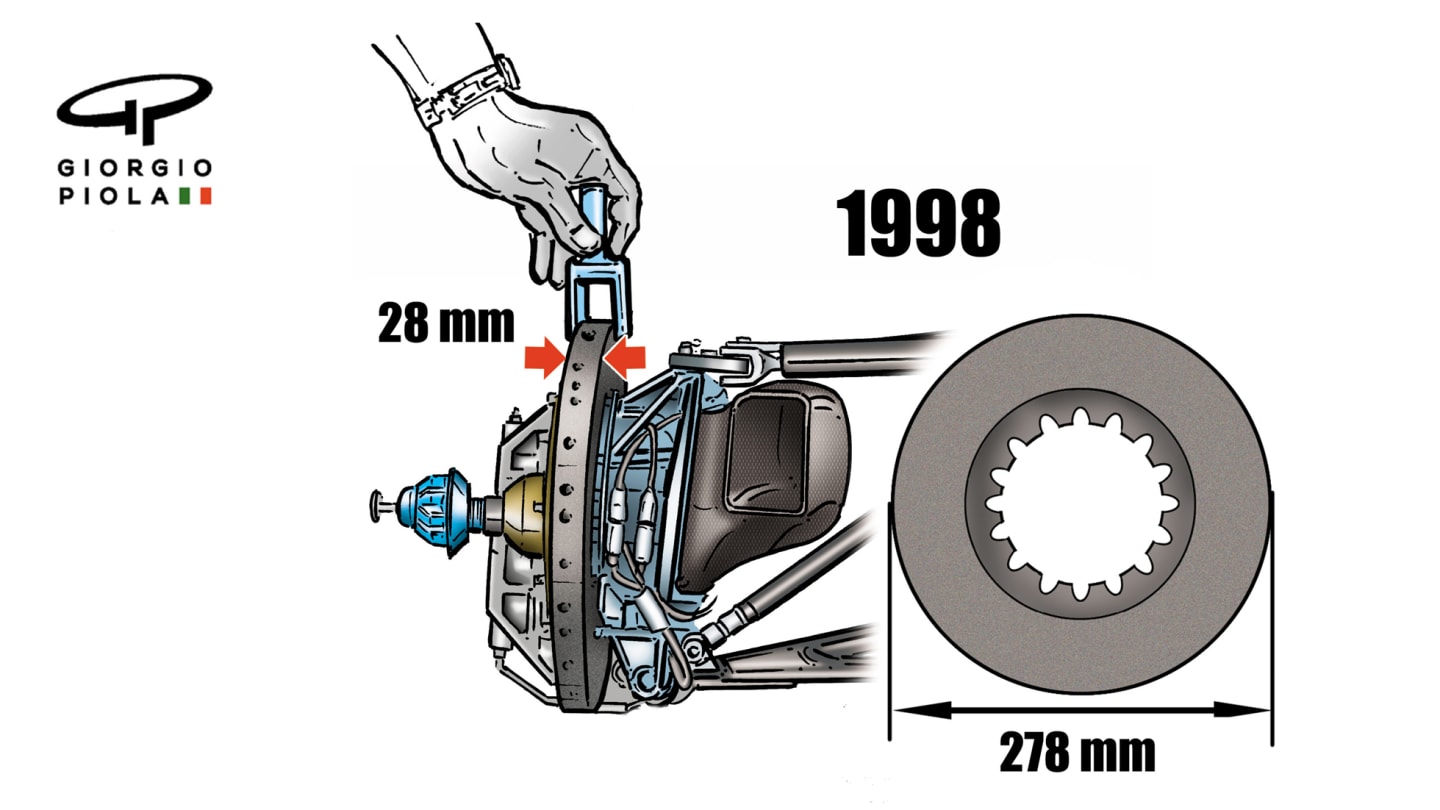

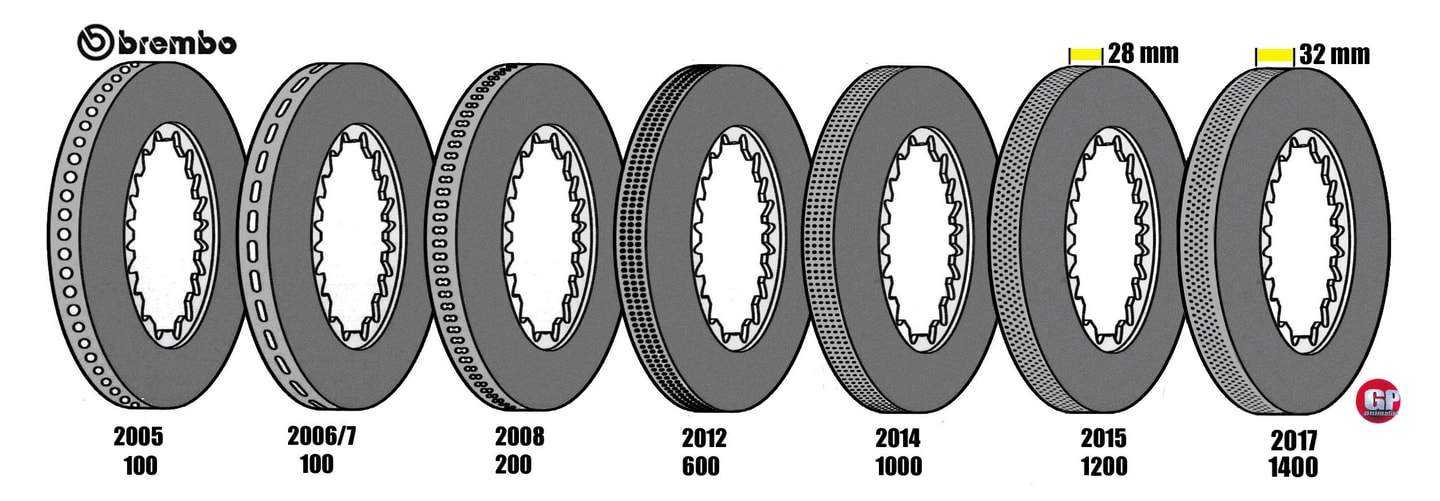

They are further limited by the regulations on brake disc size. Since 1998 the maximum disc diameter has been 278mm. A maximum width of 28mm was imposed at the same time and this latter limitation remained in place until last year when it was increased to 32mm to allow for the greater performance and weight of the new wider, more aerodynamically-powerful cars that had been legislated in. The limitation on disc size was originally made to limit increases in braking performance that were making overtaking more difficult.

The most obvious way of increasing the cooling of the brakes is to enlarge the brake ducts, forcing more cooling air onto the disc, though this comes at the expense of increased drag which limits straight-line speed.

Since 1998, maximum brake disc diameter has been 278mm. The maximum permitted width was increased from 28mm to 32mm last year to allow for the greater performance of the current generation of cars. © Giorgio Piola

Because of this loss of performance there was a drive from the teams to the brake manufacturers to improve the intrinsic cooling of the disc itself. This is very evident in the increase in the number of cooling holes within the discs over the years, whilst still retaining the component’s structural integrity. How was this possible? Essentially, through advances in materials technology.

The rate of progression has been nothing short of incredible, as can be seen in the drawing below showing the evolution of a brake disc from Brembo (one of the leading brake manufacturers in F1). The disc has gone from having 100 holes in each disc in 2005 to 1,400 today!

A greater number of smaller holes gives greater heat dissipation than a smaller number of bigger holes, and the increase in permitted disc thickness from 28mm to 32mm last year allowed the hole count to increase from 1,200.

In the hybrid era, the Montreal brake challenge has been made even more complex. With this generation of cars, much of the braking of the rear axle comes from the torque reversal upon it from the MGU-K (which converts kinetic energy generated under braking into electrical energy) as the driver lifts off.

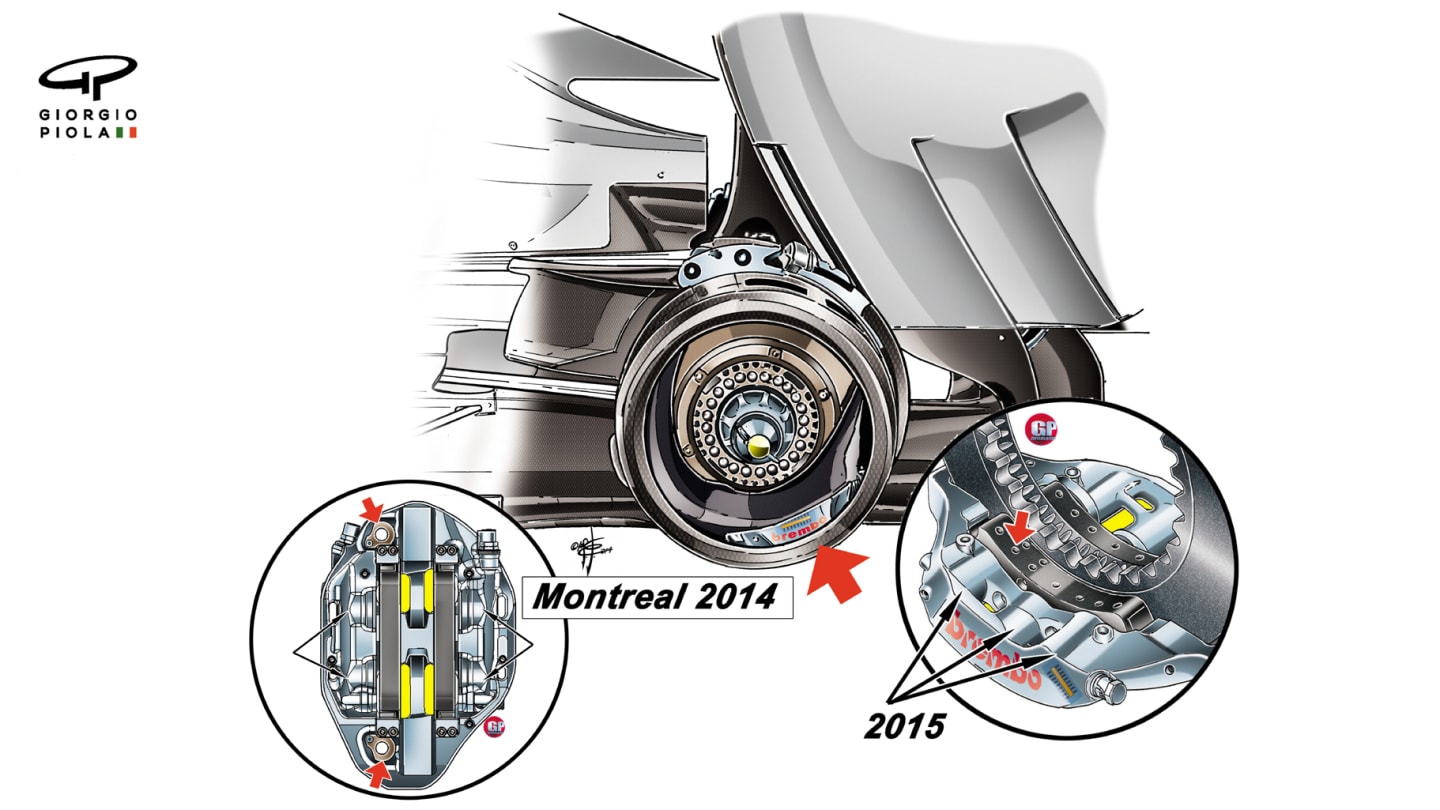

This has allowed designers to specify tiny rear brake discs in the interests of aerodynamics and minimising weight – but that makes them even more susceptible to overheating. This was demonstrated to spectacular effect in the 2014 race here when the Mercedes cars of Nico Rosberg and Lewis Hamilton both suffered failures of the control electronics for the brake-by-wire system that automatically changes the front-rear braking distribution according to whether the MGU-K is in use or not.

Lewis Hamilton had to retire when his MGU-K failed in Canada in 2014, with his rear brakes quickly unable to cope on their own. © LAT Photographic

The loss of the control electronics meant the MGU-K ceased to function and so with no torque reversal, suddenly the tiny rear discs were doing all the rear axle’s braking. This caused them to overheat within just a couple of laps, but in this instance the discs didn’t get a chance to oxidise away because the heat in the calipers and pistons caused the brake fluid to boil, leaving no rear braking.

This caused Hamilton to retire, while Rosberg – who had manually moved his brake bias forwards sooner than Hamilton – was able to keep running at a reduced pace and managed to salvage second place.

Mercedes added an extra pair of pistons in each rear brake caliper for 2015. © Giorgio Piola

For 2015 – and up to today – Mercedes increased the number of pistons in each rear brake caliper from four to six. Again, this is to do with heat dissipation as six smaller pistons can shed more heat than four bigger ones.

Mercedes' brake ducts feature slim envelope-type openings. © Giorgio Piola

Ferrari traditionally run much bigger front brake ducts than Mercedes and as a consequence the brakes can usually be pushed harder for longer. This difference can be seen quite clearly in the comparison between the Ferrari’s traditionally-shaped, semi-oval ducts and the Mercedes’ slim envelope-type openings.

1 / 2

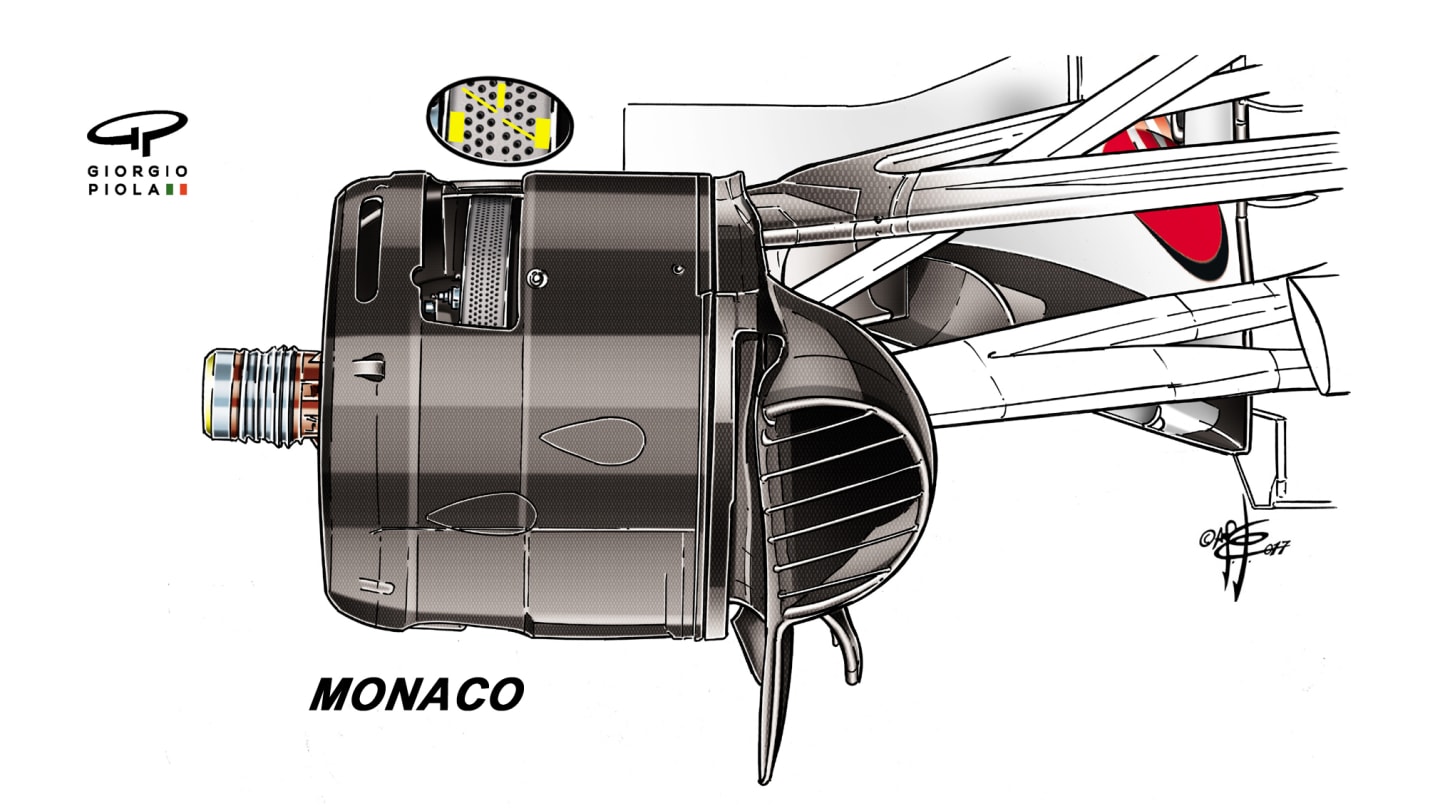

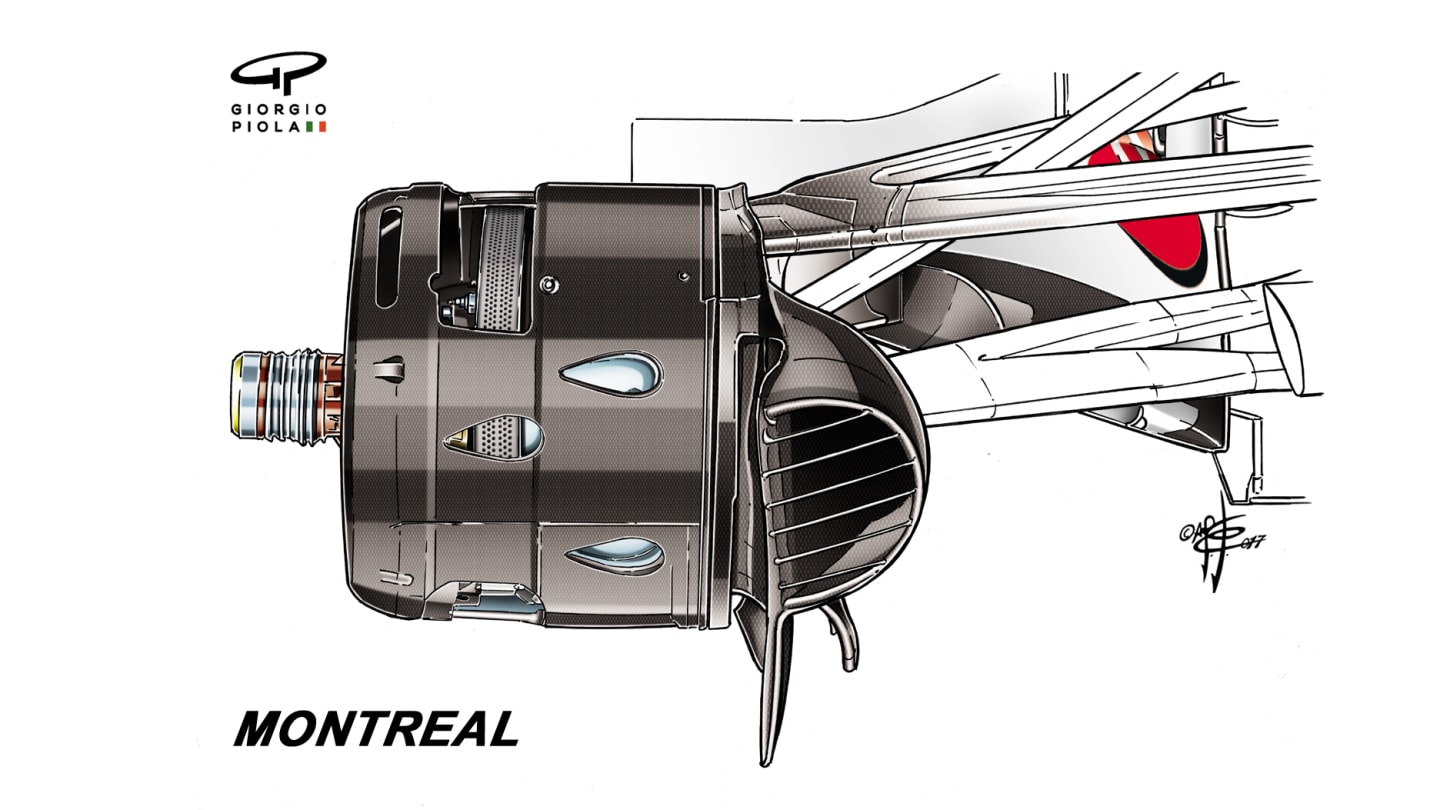

Ferrari's Monaco brake arrangement (the inset area shown in yellow is the area of un-drilled carbon)... © Giorgio Piola

The sort of Montreal-specific measures that teams make can be seen in the comparison between Ferrari’s Monaco and Montreal arrangement from last year. For Montreal the cooling holes in the drum surrounding the disc are opened out and the arrangement of the Brembo disc’s cooling holes is changed. There is a greater area of un-drilled carbon at the outer edges to give greater strength and the holes are arranged asymmetrically.

As ever in F1, it’s all about achieving the ultimate combination of performance with sufficient reliability. Montreal reveals that challenge in the area of braking more than any other track.

Access up-to-the-minute timing data, and hear team radio feeds in real time with F1 TV Access. Sign up now Only available in certain regions (view full F1 TV Content Schedule here)

YOU MIGHT ALSO LIKE

News Bottas pleased with Kick Sauber’s pace progress as Zhou rues ‘disappointing start of the year’ after Japan DNF

Feature The key differences and stand outs from the 2025 F1 calendar

News Hamilton opens up on post-F1 career options as he singles out preferred route

FeatureF1 Unlocked THIS WEEK IN F1: 10 tricky quiz questions on the Japanese Grand Prix