You might think that it’s F1’s bigger-budget teams - with more resources at their disposal - that set all of the sport’s technical trends, and the rest just follow. But actually, it often happens the other way around, as Mark Hughes and Giorgio Piola explain…

It’s not unusual to see a James Allison or Adrian Newey casting an eye over the designs of cars from the smaller teams as they gather upon the dummy grid or in the parc ferme area. For although the big team resources inevitably find the most effective interpretation of the regulations overall, often a small team can come up with detail innovation that simply hadn’t been thought of elsewhere and which is then copied and integrated on the cars of bigger teams.

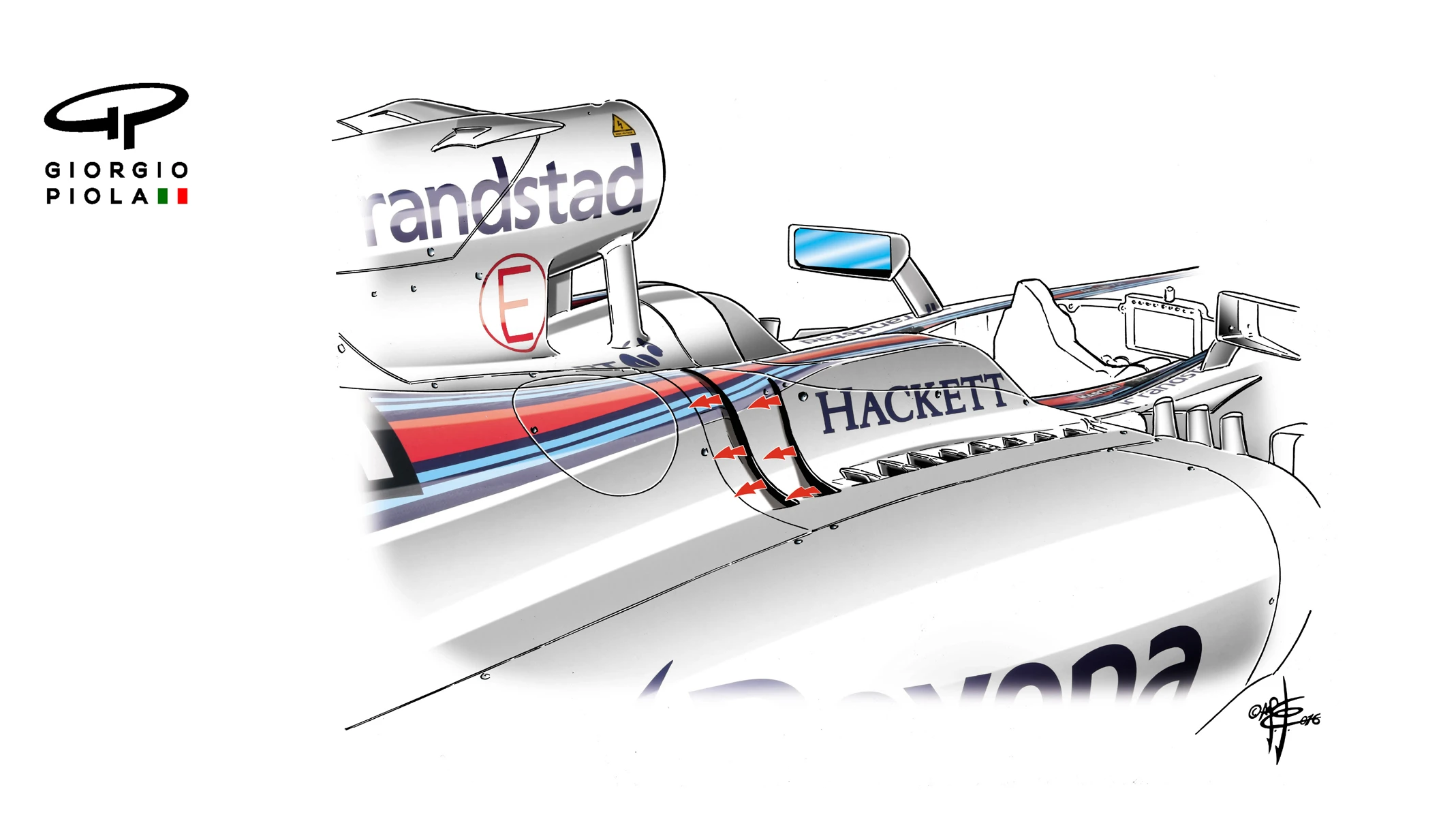

A good example of this process in action can be seen by looking at the slatted cooling outlets introduced around the cockpit by Williams in 2016 (see above). By releasing some of the hot air surrounding the radiators into an area of low aerodynamic sensitivity, the cooling slats formed by the overlapping bodywork around the cockpit sides of the Williams FW38 allowed the main radiator inlets at the front (and the outlets at the back) to be smaller and thereby less aerodynamically costly.

The horizontal gills worked in conjunction with the twin vertical slats behind. It was a detail very much part of the low-drag Williams philosophy of the time. The fast air from the free airstream moving over the top of the cockpit will be drawing the hot air from the gills faster, increasing the speed of the flow past the radiators, helping minimise their size.

Hot air from the horizontal gills forward of the vertical slats will also be extracted harder, as the flow is encouraged to merge with that exiting from the slats further back, which is itself being accelerated by the airflow coming over the top of the cockpit sides. Essentially, the three flows are being encouraged to merge into one, making for greater aerodynamic efficiency. The disruption of the air exiting the horizontal gills can also help reduce the lift created on what is quite a bluff part of the sidepod bodywork.

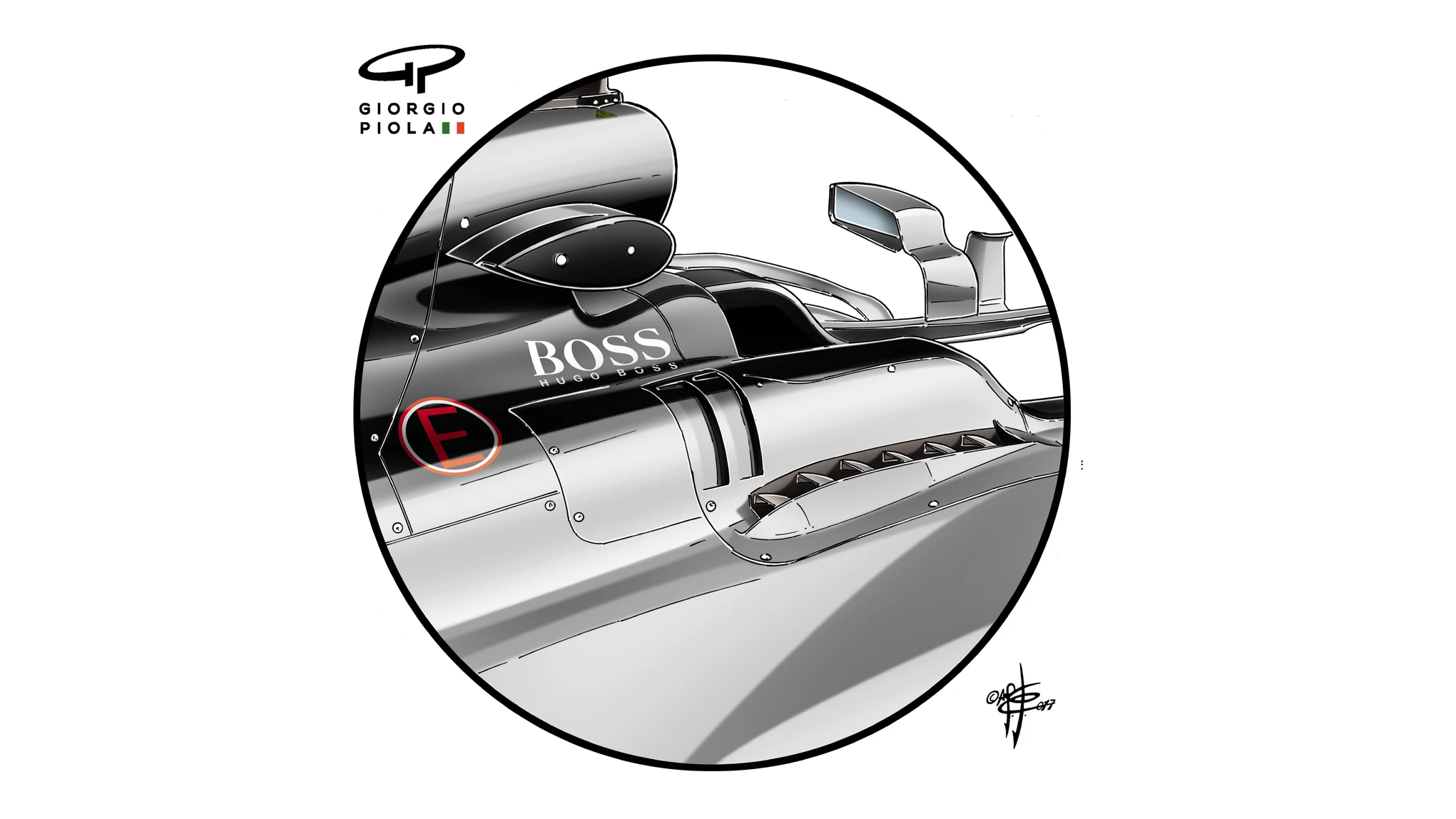

Knowing a good thing when they’d seen it, in 2017 Mercedes adopted the same principle on their world championship-winning W08 (as shown above). But they didn’t merely copy – they refined the idea further by raising the whole section containing the horizontal gills, to enhance the effect of reducing the aerodynamic lift that tends to be induced by that part of the bodywork.

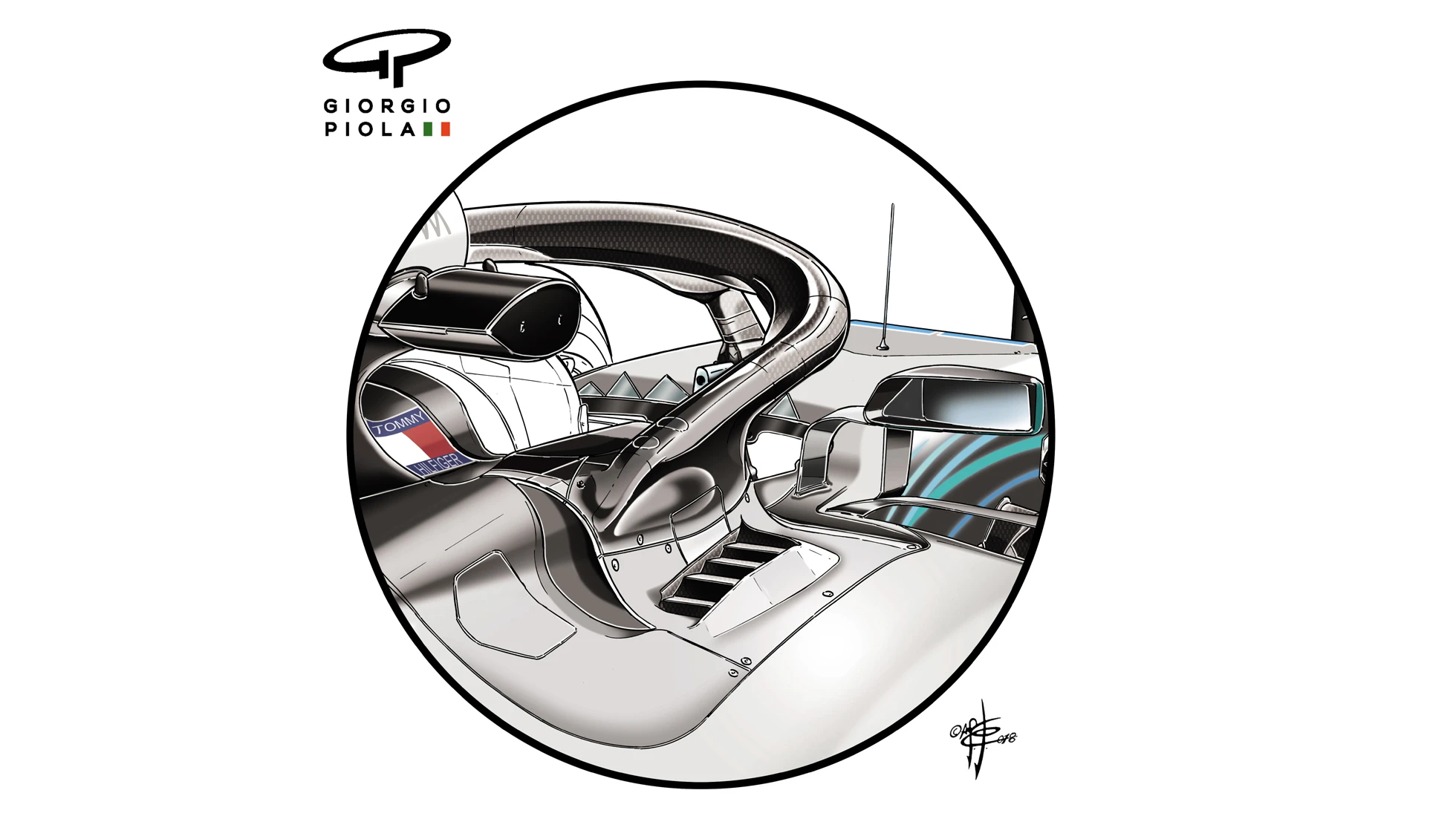

The introduction of the halo for 2018 has changed the airflow around the cockpit area and this is reflected in the further refinement of the original Williams principle on the current Mercedes W09 (shown below). The twin slats have been replaced by one bigger slat which is now inset into a contoured dip in the bodywork aft of the slat which will induce a low pressure area, pulling the air through yet faster. It can be seen how the contouring of the bodywork connecting the gills to the slat is encouraging the merging of the two flows.

Innovating in tandem

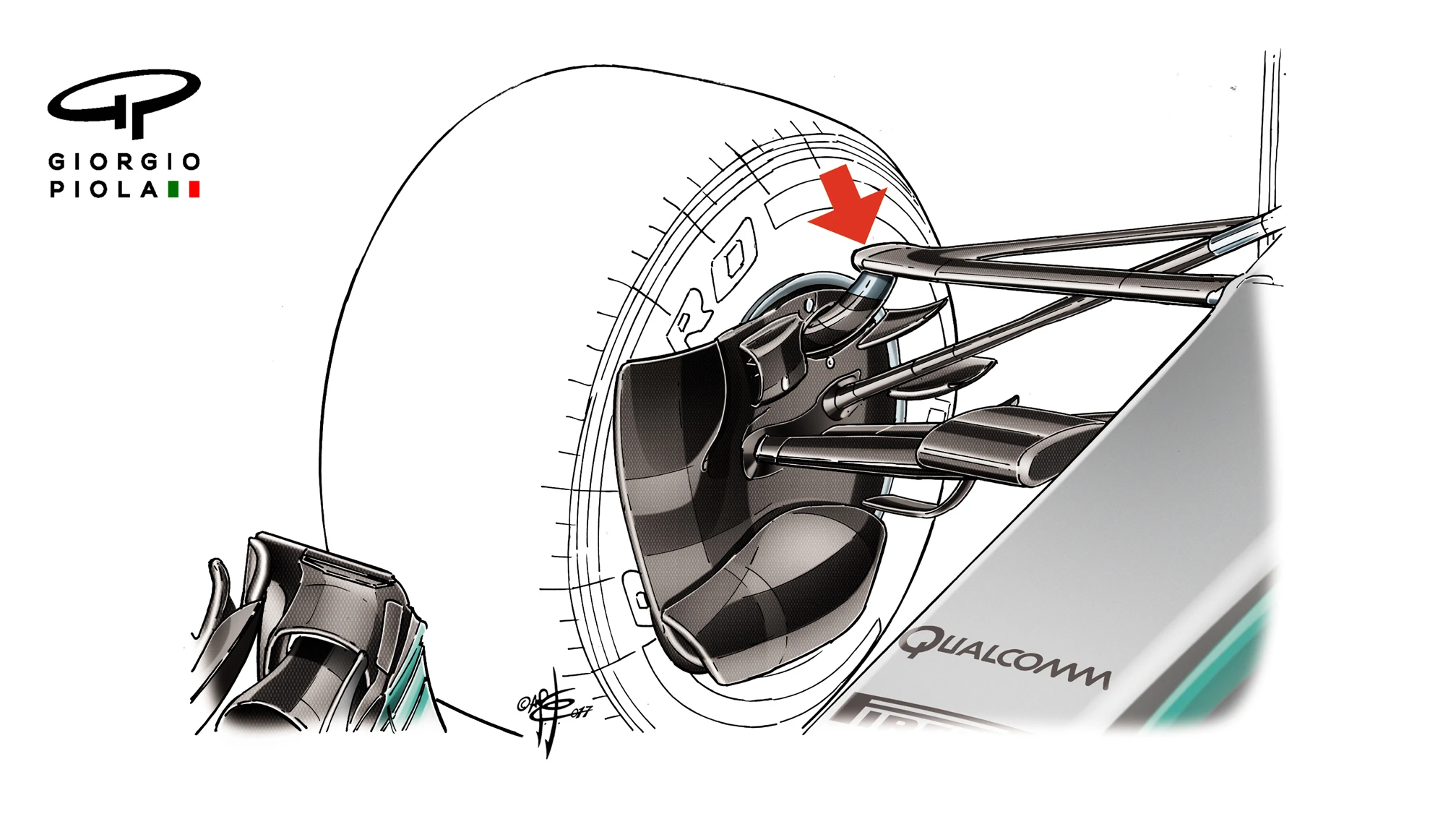

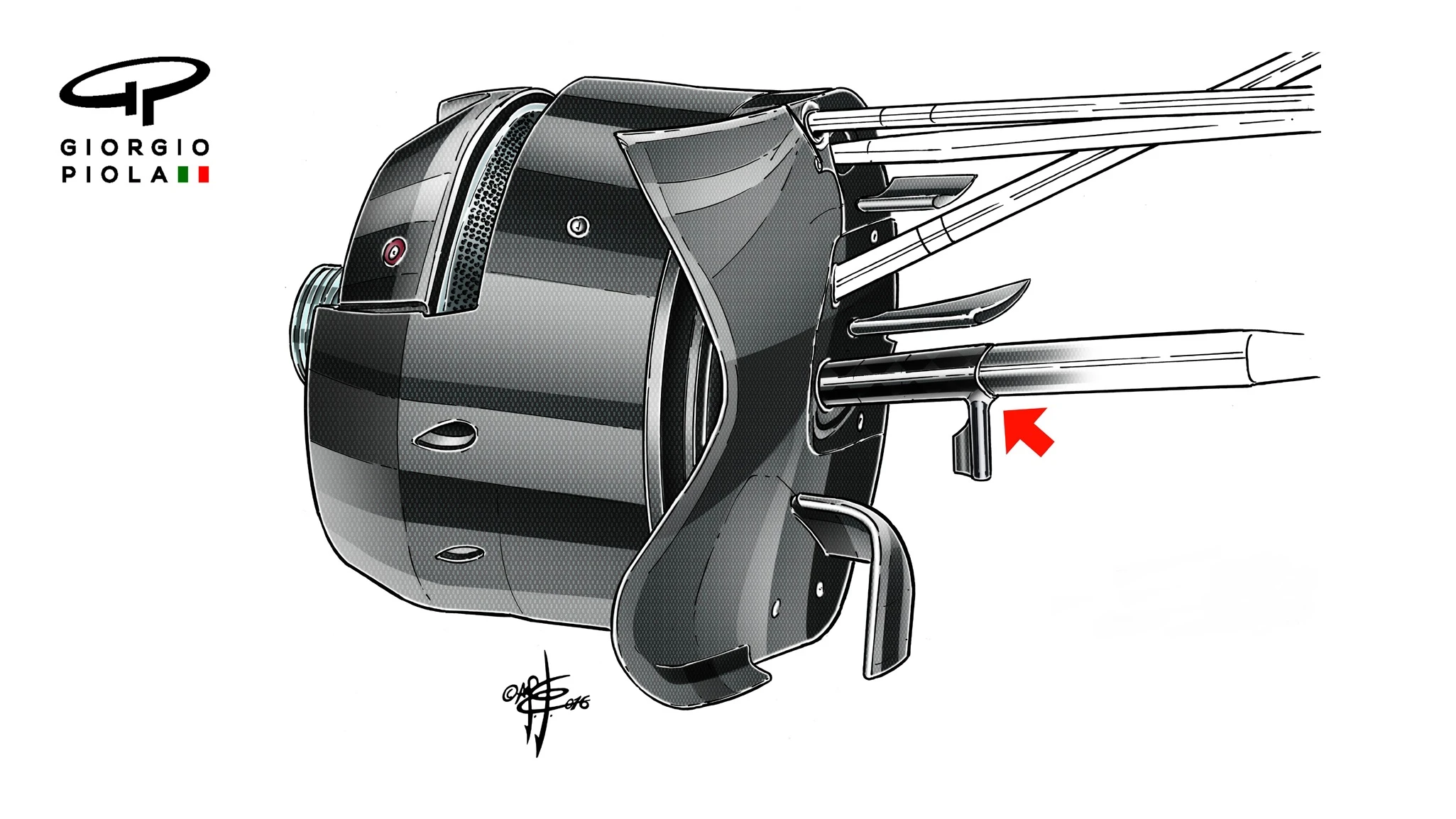

A slightly different example of small team innovation was evident last year. When Mercedes introduced their W08 they were proud of an innovation they had made with the mounting of the front suspension whereby the upper wishbone picked up from an extension to the wheel hub that allowed the wishbone to be mounted much higher, enhancing the airflow headed for the radiators (shown below).

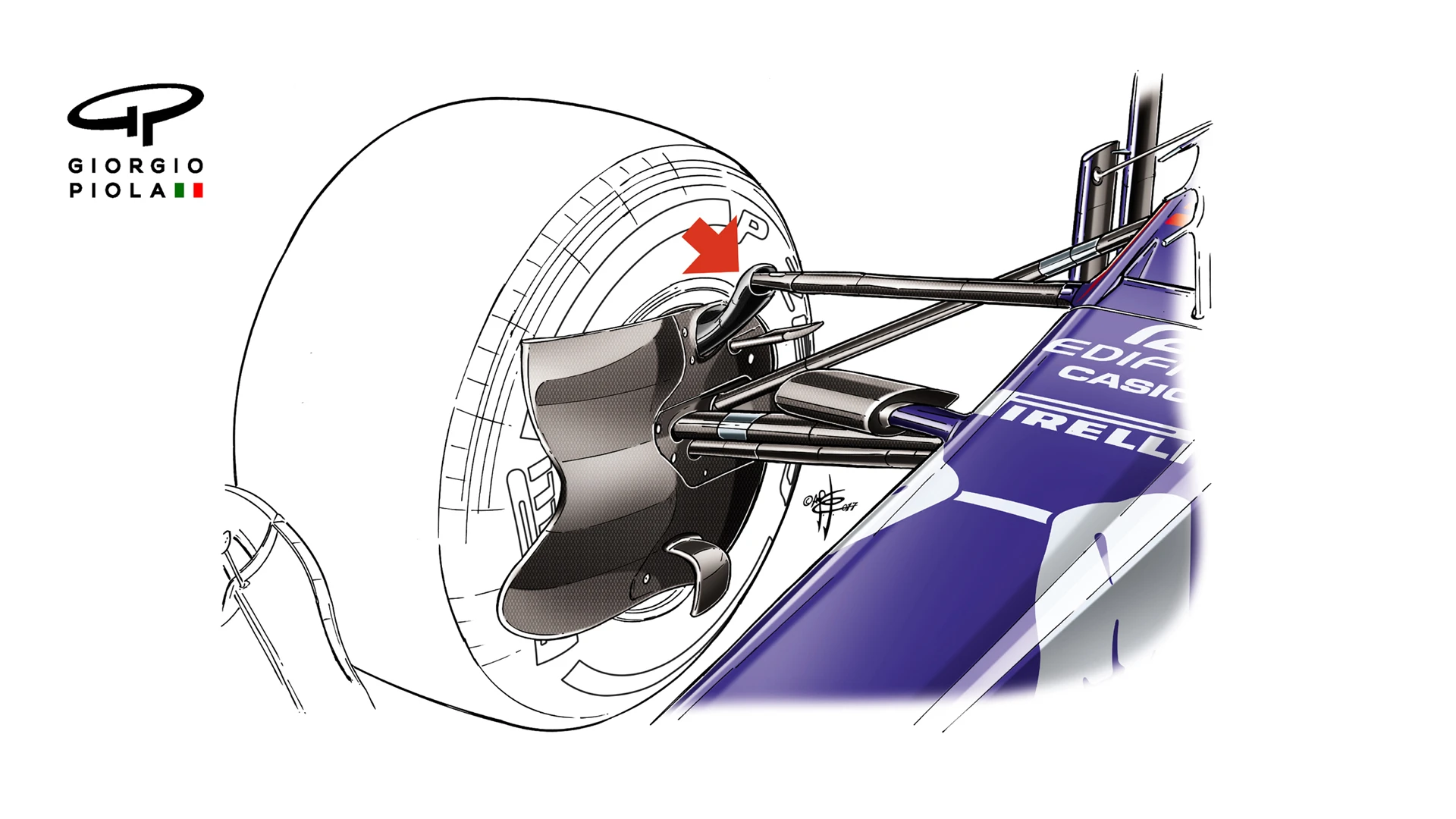

But Mercedes were then disappointed to note that the little Toro Rosso team had made the exact same innovation on their STR12 (shown below).

This choice of mounting the top wishbone on an extension to the hub is intrinsic to the choice of where the radiator inlets are placed. With a conventional mounting of the wishbone, the radiator inlets tend to be higher in the sidepods, with the main airflow to them going over the top of the upper wishbone.

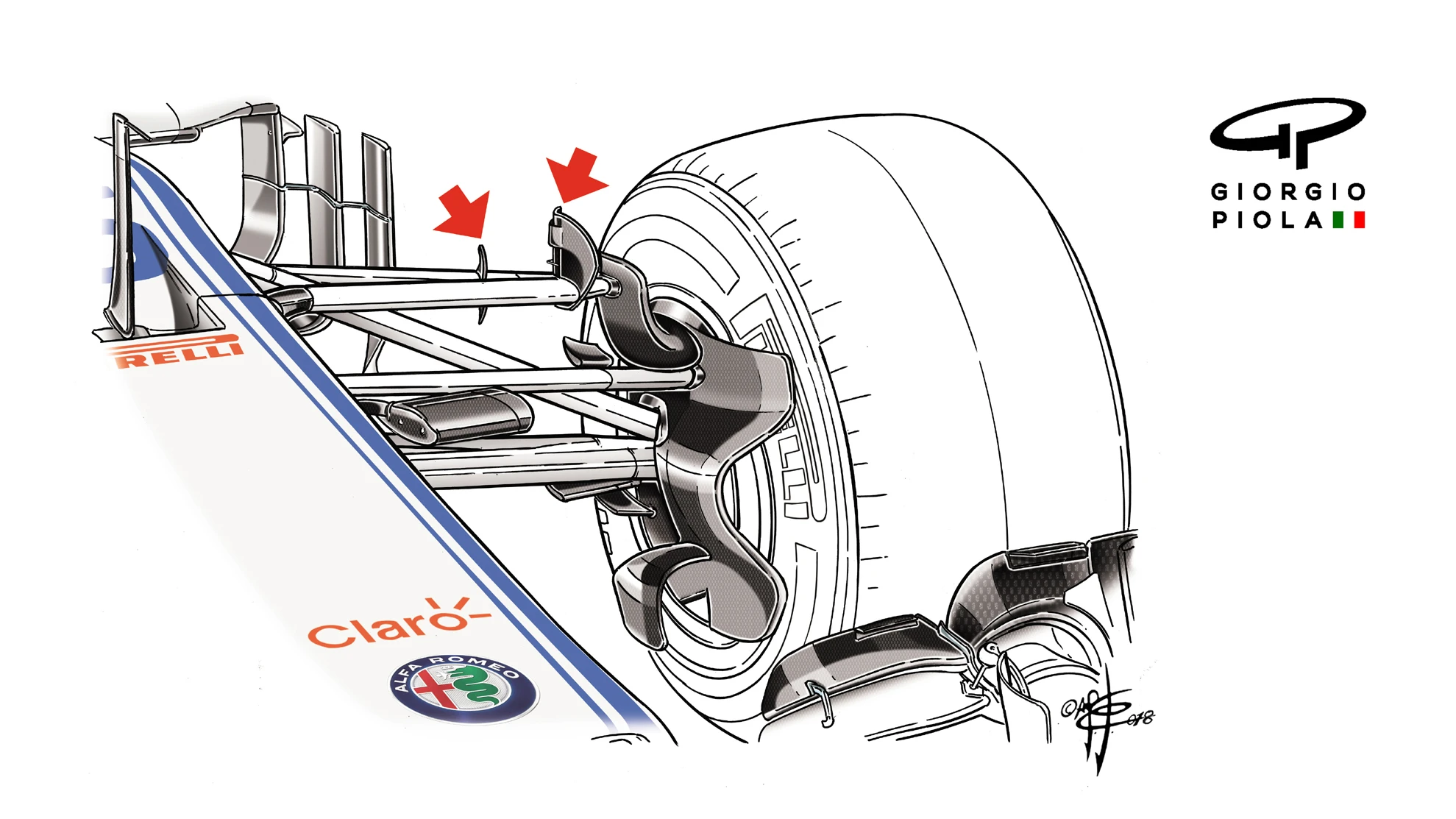

Mounting the upper wishbone higher gives the airflow a passage beneath, one which allows the radiator inlets to be lower. It’s a principle that’s been retained by both Mercedes and Toro Rosso this year and adopted also by Sauber on the new C37 (shown above). Toro Rosso’s former designer Luca Fubatto was recruited to Sauber last year and his influence can be seen also in the similarity between the aero vanes on the front suspension of 2016’s Toro Rosso and the current Sauber, which features an enhancement of the idea, with two vanes (arrowed) now working in conjunction.

The STR11 featured a small single vane (indicated by the red arrow in the picture above) that aligned the airflow coming off the front wing outwards towards fins that kept the disturbed wake of the front wheels separate from the airflow further inboard heading for the barge boards and sidepods. How the suspension vanes connect up the flow to those fins further back can be seen in the Sauber illustration.

It all goes to show, when it comes to innovation in F1, every team is pushing the limits, no matter what their resources.

Next Up

Related Articles

In NumbersHow Verstappen’s team mates fared against him

In NumbersHow Verstappen’s team mates fared against him Watch as Mercedes stage their 2026 F1 season launch

Watch as Mercedes stage their 2026 F1 season launch Newey ‘always teaching us something’ – Alonso

Newey ‘always teaching us something’ – Alonso Norris admits he’s ‘still trying to accept’ champion status

Norris admits he’s ‘still trying to accept’ champion status.webp) Russell 'ready to fight for a World Championship'

Russell 'ready to fight for a World Championship' Button joins Aston Martin as Team Ambassador

Button joins Aston Martin as Team Ambassador